Shrinkage, hot spots, dust fall-out due to erosion, and the poor mechanical properties of conventional fibre linings are universal issues kiln operators often have to deal with.

As a response to this, we developed our Refrex® Expanchor Lining System (REL® system).

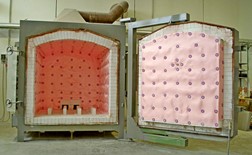

The REL® system is a combination of a flexible, dust tight, high temperature and erosion resistant fabric (Refrex®), and a simple, easy to apply anchoring system (Expanchor®).

This REL system has an excellent performance to counteract for example contamination of sanitary ceramic and porcelain products. Next to this system, our REL system offers an improved resistance of the furnace lining and a better thermal performance.

This makes the REL® system a high-performance hot face lining for new refractory linings or to upgrade the existing refractory linings in ceramic kilns, petrochemical heaters, and other types of industrial furnaces.

Since 1996, the REL® system has been successfully applied in sanitary shuttle and tunnel kilns, porcelain and glazed earthenware kilns, dust free thermal process kilns (Electronic components). Also in (dust free) heat treatment kilns Laboratory- and test kilns, annealing lines, low thermal mass lined hot gas ducting Petrochemical heaters (roof sections) and combustion chambers.

For further information, please contact us or use the questionnaire below. Also you will find our leaflets for the Petro-chemical, Ceramic and Steel Industry. A reference list is available upon request.

Looking for advice? We will help you to find a suitable solution! Give us your details and we will contact you as soon as possible.